If you are getting your house ready for a Truth in Housing inspection, your home’s plumbing is one of the major areas that the inspector is going to evaluate. And one of the most common deficiencies that is likely to be found is in your toilet tank. Minneapolis Truth in Housing guidelines require (and the other cities with Truth in Housing ordinances are similar) the evaluator to determine that all toilets “are provided with an anti-siphon ballcock that is properly installed (with the critical line at least one (1) inch above the opening of the overflow tube).” I’d estimate that close to one half of the toilets I look at do not meet this requirement and, therefore, need a simple fix.

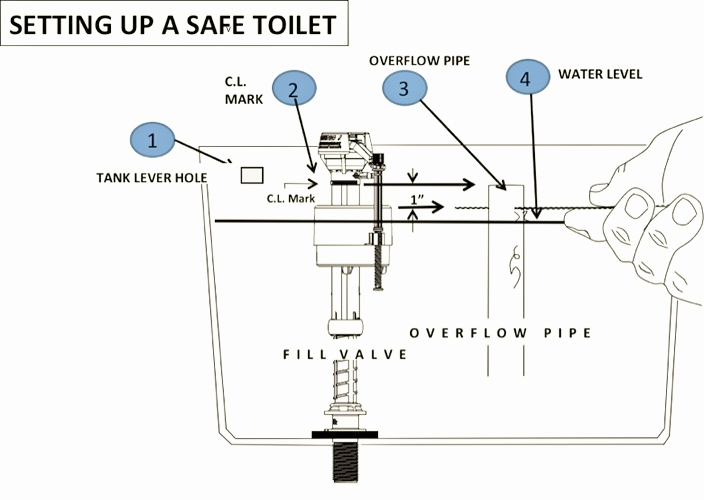

To understand what your city requirement is, and what the evaluator is looking for, we can use the following illustration:

The Truth in Housing requirement is really just about two of the components seen here. And here’s a hint: it has nothing to do with the level of the water (a common misconception). What the evaluator is going to look at is the height of the overflow tube (seen at the center of the illustration) in relation to the toilet critical line (seen near the top of the fill valve at the left). On Fluidmaster brand valves like the one in the illustration, the critical line (CL) is a raised ridge of plastic that can be both seen and felt, near the top of the filler valve.

The typical Truth in Housing scenario that requires a fix is that the overflow tube is too high. Remember, the requirement is for the top of the tube to be at least 1″ below the critical line (CL). This can be corrected by either of two methods. First, the top of the overflow tube can be cut to a level that is at least one inch below the CL mark on the fill valve. This is the method that is being shown in the illustration. The second method is to raise the fill valve until the CL mark is at least one inch above the top of the overflow tube. With Fluidmaster brand valves, this is not difficult to do. But it is my opinion that cutting the overflow tube is the simpler of the two methods because it doesn’t require you to get your hands all the way inside the tank and make adjustments to components that are hard to see. Note that once either adjustment is made, a second adjustment to the float mechanism may be needed to get the water to shut off at a lower level. If you don’t adjust the float mechanism, you might find that the water never shuts off because it is now running down the overflow tube before the float can reach the level that cuts off the water supply. This will be both irritating and expensive.

If you find yourself asking what the reason is for this requirement, the simple answer is that it is an anti-siphon measure. The Fluidmaster website states that adjusting the fill valve so that the CL mark “is 1 inch above the top of the flush valves ‘overflow pipe’ will properly set the valves anti-siphon design and, in times of emergencies, will not let the tank water siphon or get sucked back into the main water supply.”

I’m all for clean water. And if a simple adjustment to a toilet’s inner components will keep dirty tank water from contaminating a home’s, and potentially the city’s, water supply, it’s an effort that is well worth it.